Magnetic screw conveyor|Bunri is a specialized manufacturer of equipment that separates and discharges sludge and chips from grinding and cutting

Powerful magnetic screw conveyor SCC

Magnetic screw conveyor SC

Powerful vertical magnetic screw conveyor VS

Screw t ype conveyor using magnet.

The rotating part is not exposed, so this can be used safely and se curely.

Optimum for cutting chip processing of gear cut ting machines, broach machines, etc.

Features

- The rotation axis of the magnet is inside the fixed pipe, so there are only a few problems such as chip biting, which enables you to use this product safely.

- Also suitable for dry processing based on the heat resistant specifications.

- This product does not use any consumables such as cartridges or paper filters, so no industrial waste is generated.

| Coolant | Water soluble Oil-based |

|---|---|

| Category | Magnetic material |

| Processing details | Cutting |

| Work material | FC/FCD Steel |

| Chip shape | Granular Small curl-shaped (50 mm or less) |

| Grinding chip size | |

| Machine tool | Machining center Broaching machine Gear cutting machine |

Product introduction video

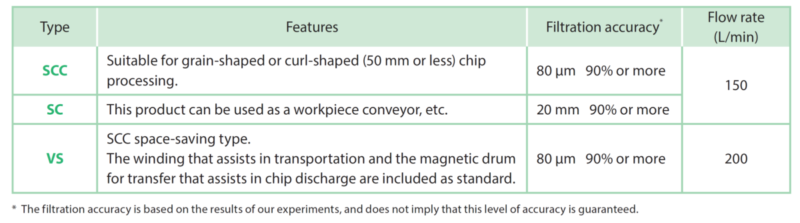

Features of 3 Type

SCC

- Suitable for grain-shaped or curl-shaped (50 mm or less) chip processing.

SC

- This product can be used as a workpiece conveyor, etc.

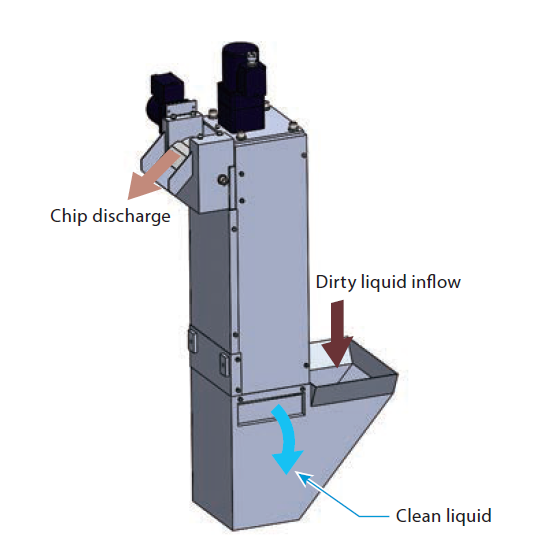

VS

- SCC space-saving type.

- The winding that assists in transportation and the magnetic drum for transfer that assists in chip discharge are included as standard.

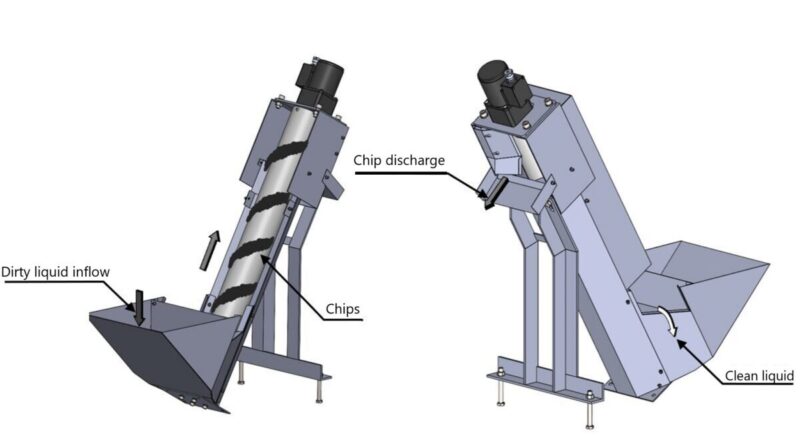

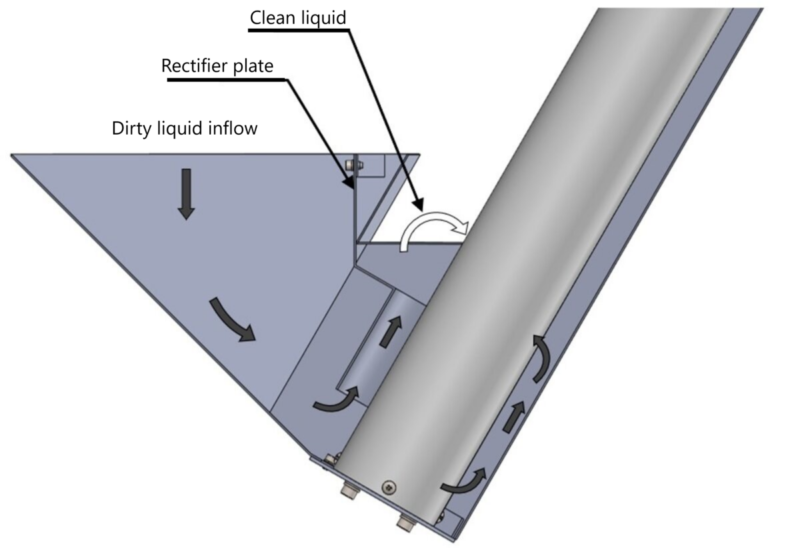

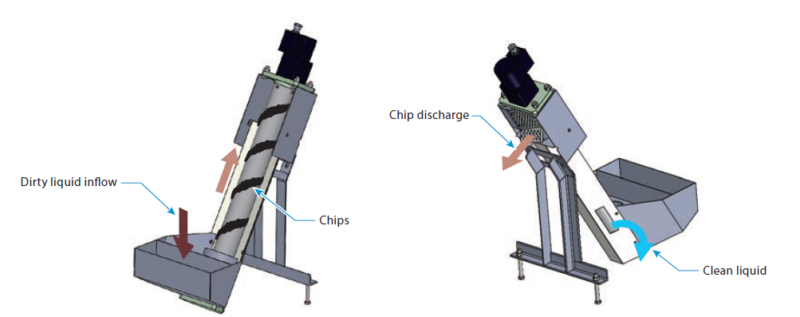

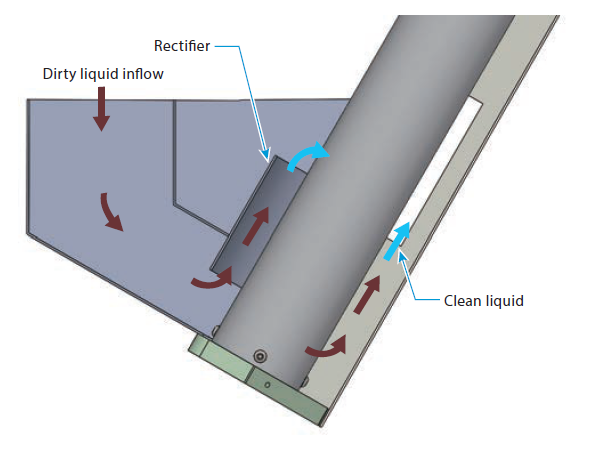

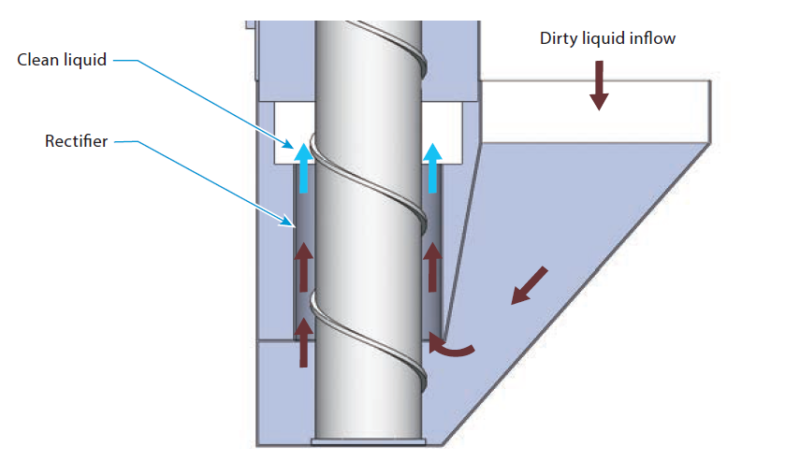

Mechanism

SCC

SC

- The dirty liquid flows onto the conveyor.

- Chips are absorbed and captured by the magnet inside the fixed pipe.

- By rotating the magnet shaft inside, chips are discharged while moving on the surface of the pipe.

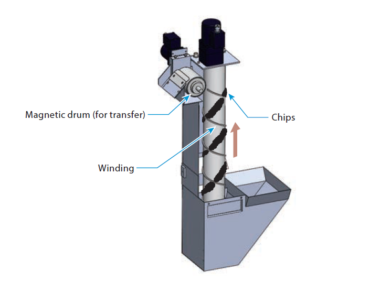

VS

- The dirty liquid flows onto the conveyor.

- Chips are absorbed and captured by the magnet inside the fixed pipe.

- By rotating the magnet shaft inside, chips are transported to the top of the main body while moving on the surface of the pipe.At that time, the winding assists transportation.

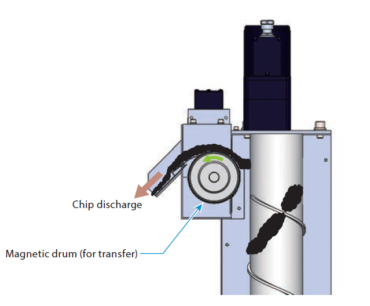

- Chips fall from the pipe onto the magnetic drum (for transfer) near the outlet, and are discharged

Specifications

SCC・SC

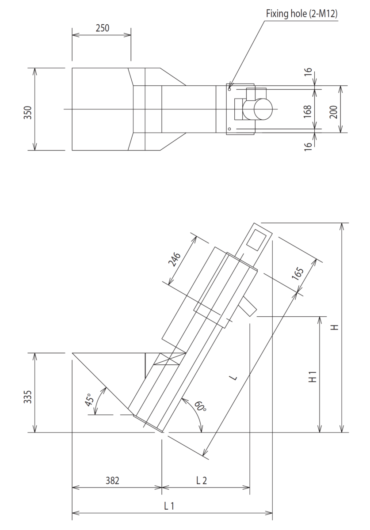

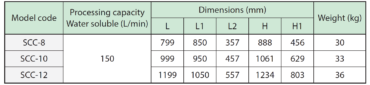

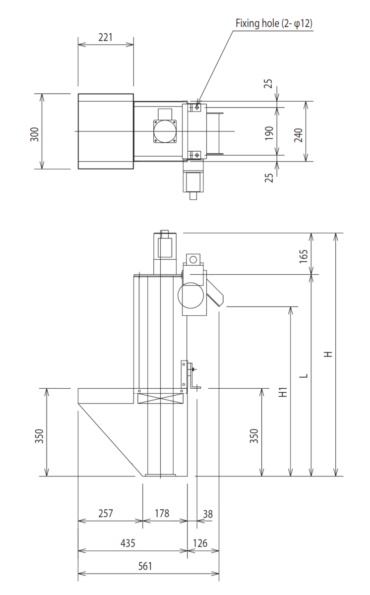

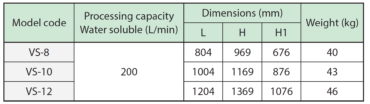

VS

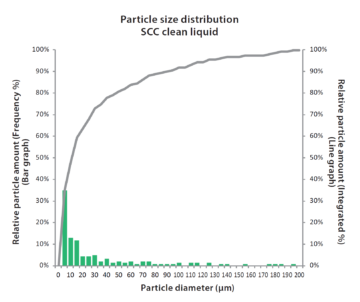

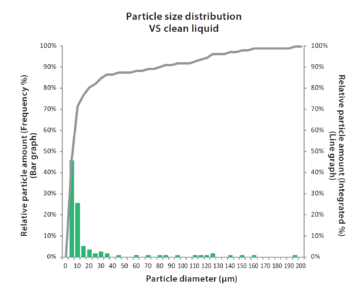

Filtration accuracy

- SCC 80μm 90% or more

- SC 20mm 90% or more

- VS 80μm 90% or more

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

Sludge distribution status

SCC

Machine tool: Machining center

Coolant: Water soluble

Processing flow rate: 50 L/min

Chip material: S45C

VS

Machine tool: Machining center

Coolant: Water soluble

Processing flow rate: 120 L/min

Chip material: Steel

Processing flow rate

Water soluble

- SCC 150L/min

- VS 200L/min

Product weight

- SCC-8 30㎏

- SCC-10 33㎏

- SCC-12 36㎏

- VS-8 40㎏

- VS-10 43㎏

- VS-12 46㎏

* The product weight varies depending on the specifications, options, etc.

Paint color

Medium metallic (Approximate color: Munsell No. N-6.7)

* For information about the specified color, please consult us.

Drive motor

- Drive motor 40W

- Transfer drum motor 25W

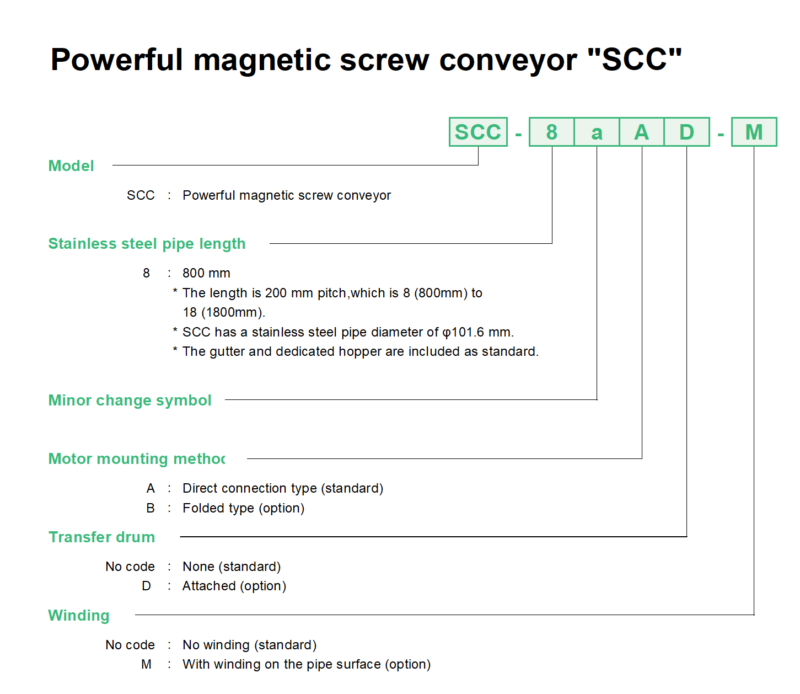

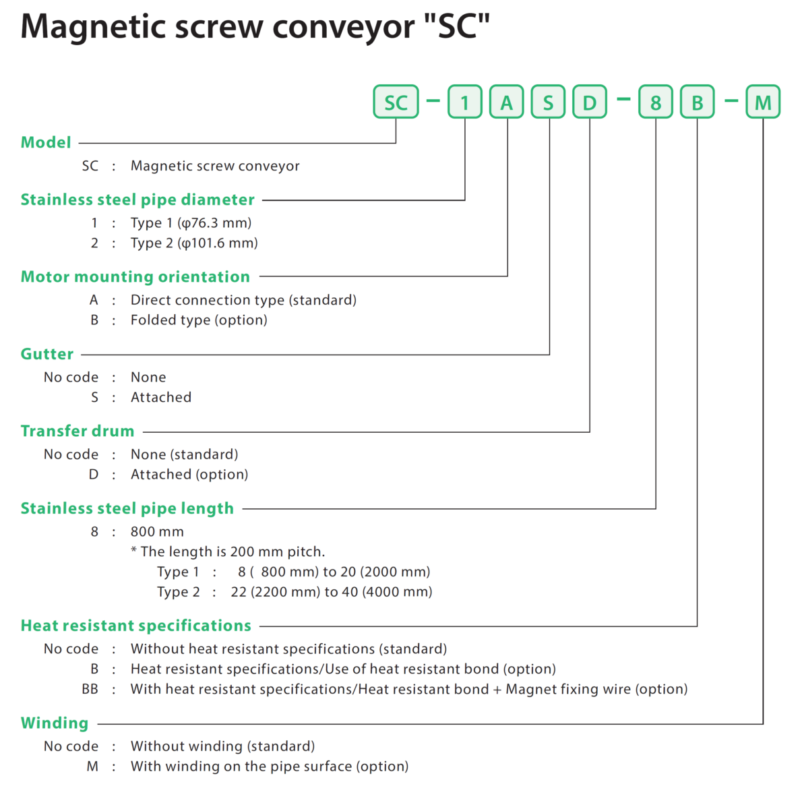

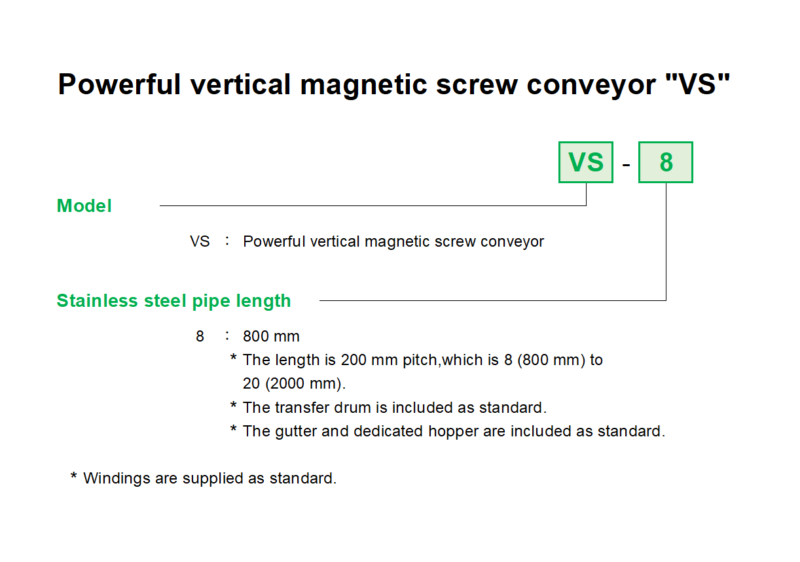

Model code

SCC

SC

VS

Product Photo (Example)

SCC・SC

VS

Chip discharge image

* Photos are product images for illustration purposes only. Specifications differ from the actual product.

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

* The specifications and dimensions are subject to change without notice.

* For the oil-based specifications, please consult us.

* For information about custom products other than standard products, please consult us.

Catalog-Download

You can download a comprehensive catalog that covers Bunri's products.