Magnetic separator Phoenix NEO|Bunri is a specialized manufacturer of equipment that separates and discharges sludge and chips from grinding and cutting

Magnetic separator Phoenix NEO

Magnetic separator using rare earths, which has about 10 times the magnetic energy* of ferrite.

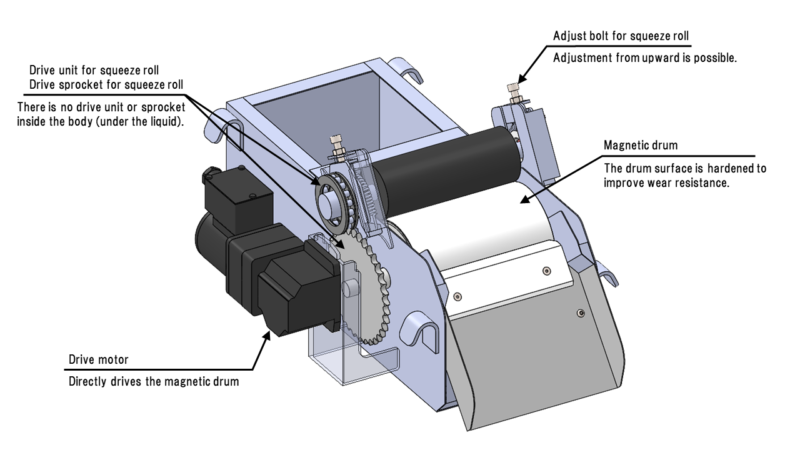

By renewing the drive mechanism of the magnetic separator, there is no wear due to sludge or abrasive grains.

A lineup of four models is provided to suit your requirements.

<PATENTED>

Features

- Typical coolant filtration unit that filters grinding sludge of magnetic materials.

- Because the driving part (chain/sprocket) is installed outside the main body, there is no wear due to sludge or abrasive grains. In addition, parts replacement and maintenance are easy.

- The magnetic drum has improved wear resistance due to surface hardening treatment.

- Since it is a squeezing roll with a sprocket, it suppresses slip caused by sludge and oily coolant. In addition, by changing the adjustment mechanism of the squeezing roll,adjustment of the squeezing condition and maintenance have become easier.

- This product does not use any consumables such as cartridge filters or paper filters, so no industrial waste is generated.

- We have a lineup of four models with different strength magnets and magnetic drum diameters.It is possible to select the optimum separator to suit the customer’s processing conditions and the required filtration accuracy.

* Maximum energy product

| Coolant | Water soluble Oil-based |

|---|---|

| Category | Magnetic material |

| Processing details | Grinding |

| Work material | FC/FCD Steel |

| Chip shape | Sandy Cottony Granular Needle-shaped |

| Grinding chip size | Ultrafine particles (5 μm to 10 μm) Fine particles (10 μm to 100 μm) Coarse particles (0.1 mm to 0.5 mm) |

| Machine tool | Grinding machine Tool grinding machine Saving machine Honing machine Super finishing machine (Super finisher) Thread rolling machine Induction hardening machine Washing machine |

Product introduction video

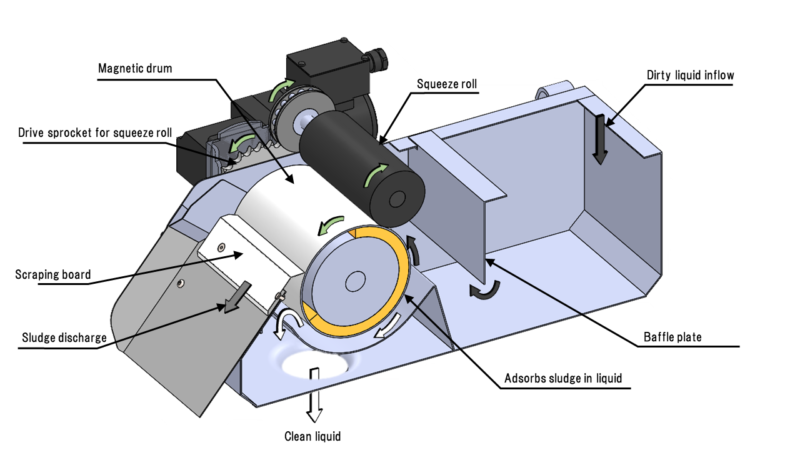

Mechanism

- When the dirty liquid that flowed into this machine passes through the filtration section (magnetic drum), the sludge in the liquid is adsorbed by the magnetic force of the magnet, and filtered.

- After filtration, the clean liquid is discharged to the outside of the main body.

- The adsorbed sludge is as a result of the rotation of the magnetic drum.The water in the sludge is dehydrated by the squeeze roll.

- The dehydrated sludge is scraped off by the scraping board that comes in contact with the magnetic drum, and discharged to the outside of the main body.

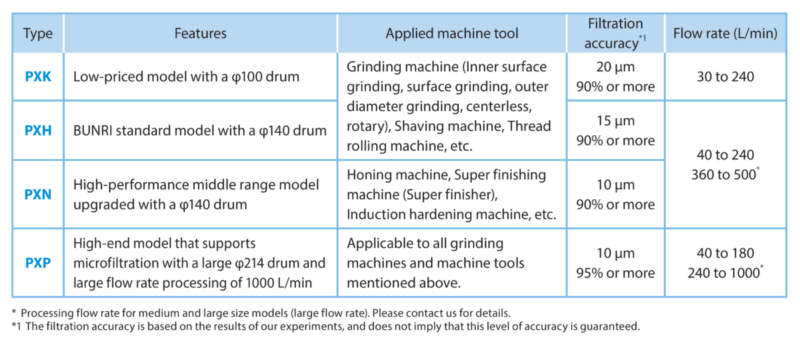

Comparison of 4 Type

- PXK Low-priced model with a φ100 drum

- PXH BUNRI standard model with a φ140 drum

- PXN High-performance middle range model upgraded with a φ140 drum

- PXP High-end model that supports microfiltration with a large φ214 drum and large flow rate processing of 1000 L/min

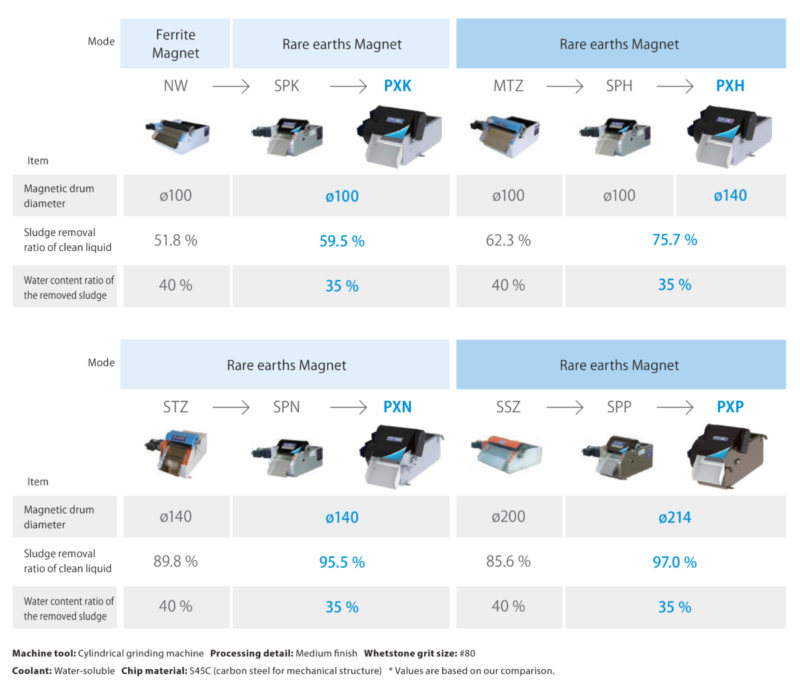

Comparison with old models

Comparison with old models

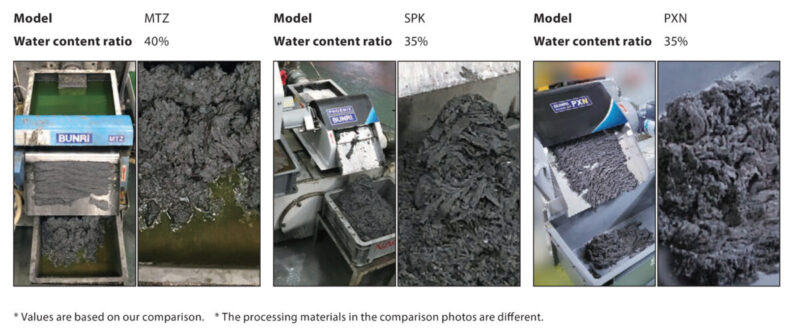

Comparison of water content ratio of removed sludge

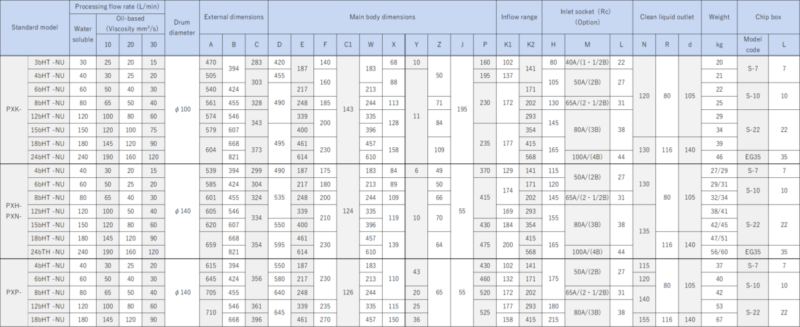

Specifications

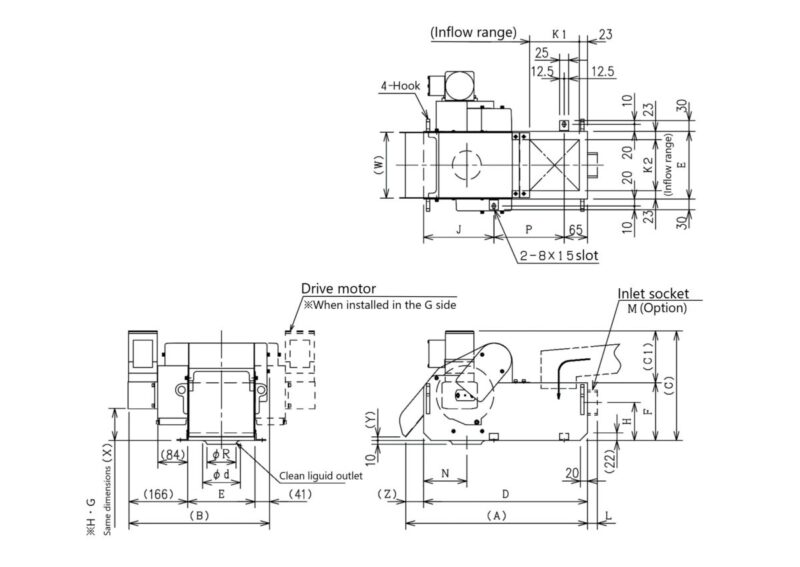

Dimensional drawing

Dimension table

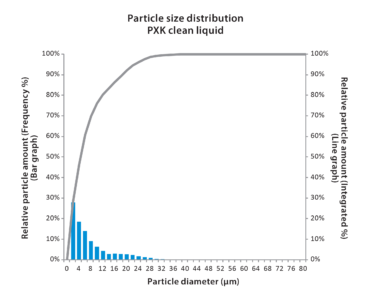

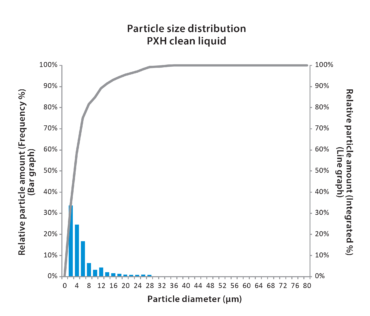

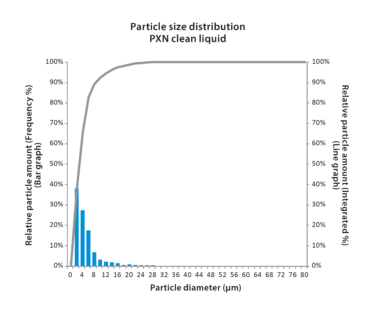

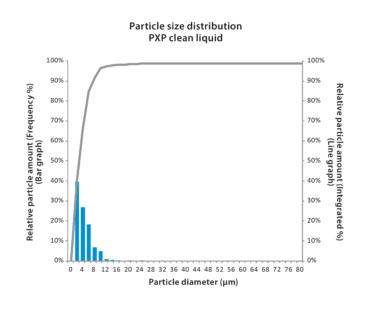

Filtration accuracy

- PXK 20 μm 90% or more

- PXH 15 μm 90% or more

- PXN 10 μm 90% or more

- PXP 10 μm 95% or more

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

Sludge distribution status

Machine tool: Inner diameter grinding machine Coolant: Water soluble Processing flow rate: 60 L/min Chip material: Steel

Processing flow rate

Water soluble

- PXK 30 to 240 L/min

- PXH 40 to 240 L/min

- PXN 40 to 240 L/min

- PXP 40 to 180 L/min

* We also provide medium and large size models (large flow rate). Please contact us for details.

Product weight

- PXK 20 to 46 ㎏

- PXH 27 to 56 ㎏

- PXN 29 to 60 ㎏

- PXP 37 to 67 ㎏

* For details, please check the product dimensions.

* The product weight varies depending on the specifications, options, etc.

Paint color

- PXK Medium metallic (Approximate color: Munsell No. N-6.7)

- PXH Medium metallic (Approximate color: Munsell No. N-6.7)

- PXN Medium metallic (Approximate color: Munsell No. N-6.7)

- PXP Champagne gold (Approximate color: Munsell No. N-2.5Y6/2)

* For information about the specified color, please consult us.

Drive/geared motor

25W

* The medium and large size models have different specifications.

Option

- Inlet Socket,nipple,pipe,flange

- Outlet With socket on the left and right sides

* Please contact us for details.

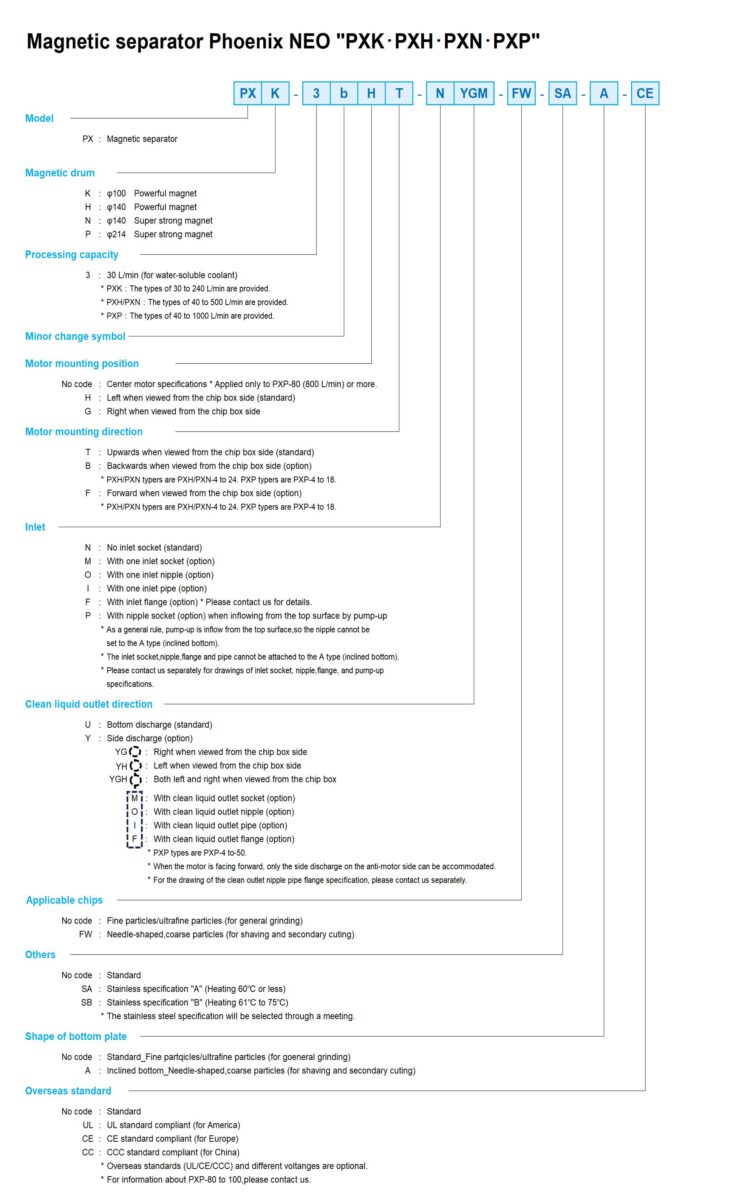

Model code

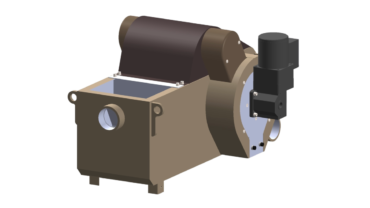

Product Photo (Example)

Standard without inlet socket, Bottom discharge

Option with inlet socket, Side discharge

With tank, pump, and liquid level gauge

Chip discharge image

* Photos are product images for illustration purposes only. Specifications differ from the actual product.

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

* The specifications and dimensions are subject to change without notice.

* When the oil viscosity exceeds 30 mm2/s, please consult us.

* For information about custom products other than standard products, please consult us.

Catalog-Download

You can download a comprehensive catalog that covers Bunri's products.